Keep it comming ascort this is intresting stuff :beer:

Andy W

AW wrote:

Thanks for that Andy. I have to keep looking around for my photos. It is a crazy fact that I have been putting a large effort in to collecting and collating information on the Ascort History, but have been very slack in recording the work that I have been doing on my own car.

:cry:

I still have a few things to add yet, but thought that it is best to spread the posts out just a little.

One of the problem areas of my #005 is the doors.

Ascort doors must have always been a bit of a problem as if you look very closely at early photos of the D72 prototype, and early magazine articles where the car is featured, you will not see the windows up and it also has no window winders.

(The prototype looks to have had Karmann Ghia door catches, - tell me if I am wrong, while all of the later cars had VW beetle catches and striker plates.)

In interviews, Mirek Craney states that the getting the frameless windows working was a real problem that took some sorting. I also have seen a 1959 list of issues that need attention on the Ascort to improve the design and high on the list was issues with the fit of the windows and draft issues at the bottom of the doors.

When I purchased my Ascort it was missing its window regulators and the drivers door was missing its window regulator mounting brackets. At least the doors did have the window channels and glass. For the last 30 years I have been looking for the correct winder mechanisms for the doors without success. I have to admit that it is the only significant part that I cannot recognize the origins of.

I considered trying to find something else that fitted, but all of the regulators that I tried either just did not fit or put the winder handle in a different location. Some years ago I at least got to see what the original regulators looked like when B. brought his blue drag racing Ascort 2000 km to town for the National VW Drags. (This Ascort was never completed and has never been on the road)

In a moment of stupidity I decided that if I cannot find an original, I would just have to make my own. Surely it could not be that hard, I have made my own emblems, my own 1:43 scale models, done the dash etc, so surely I could make these.

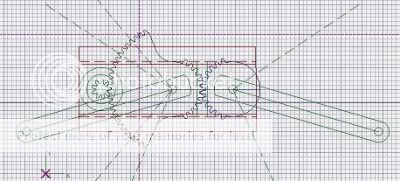

I started by finding some old regulators that I could strip apart for components (the primary gear and mechanism including the square winder shaft). I then went to the car and measured how high the glass needed to lift and lower, where the original position of the winder handle fitted, what the size of the mounting frame needed to be, etc.

I then worked out what the pitch of the primary gear was, how long the arms needed to be, and what arc angle the arms needed to operate through with the mechanism mounted in its original location. This was all drawn in CAD, following the same design principles as the originals. (The arms in this drawing are shorter than they should be).

The components were then separated into separate CAD files and taken to my friendly man with the waterjet cutting machine. Once again the compatability problems came up and would not resolve and so the drawing was changed to a .pdf format with a scale provided to ensure that I got full size components. The quadrants, gears and base frame were then cut and the base frame folded to get the required recess depth.

I am only part way through building my regulators as I think that I keep getting chicken and avoiding doing the work on them. The primary gear has a temporary mount with some clecos, the bush for the shaft is mounted, the pivot holes are drilled and reamed and I have now started on the pivot shafts.

I still have a way to go. :unsure:

8) :beer:

PS. I forgot to mention that my blue car has different mechanisms and mounts ... but I don't know what they are either at this stage.

Edited by user

11 years ago

|

Reason: Not specified

Mark - Owner of 2 under restoration Australian coachbuilt Ascorts.