The restoration of the Ascort can be a mixture of easy and hard.

Many parts used in the cars were common parts taken from VW, Porsche and some other makes, which means just searching for the bits.

Other things are things are much more difficult as they were unique to the cars. One example of this is the emblems for the cars. It would seem that not all cars had emblems when they were built new and very few emblems now remain. (Only a few rears and maybe one front - which I have not been able to access)

Once the paint was removed from my car the filled holes could easily be seen,showing that my car had a full set of emblems when first built. It would seem that these were removed early in the car's life as the first repaint was done in its first year of life and this covered the emblem holes. I just had to have emblems for my car but as none were available it meant creating my own.

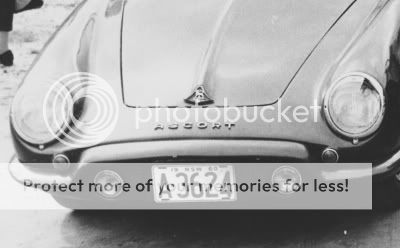

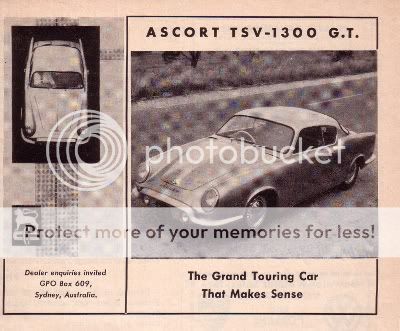

This is what was required for the front. The logo on the advertisement was also used as a guide.

I enlarged every old photo that I could find that showed the front emblem and then played with the size until I could get the profile of the front emblem to cover the original mounting holes in a position on the emblem where it would be logical to have the mounting screws.

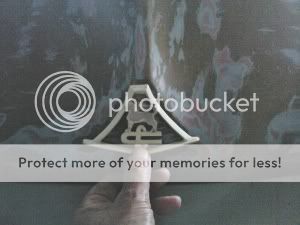

A balsa wood version of the emblem was created on the photo enlargement, with the advertisement logo used to help with fine detail.

Once the rough balsa version was made a trial fit was done.

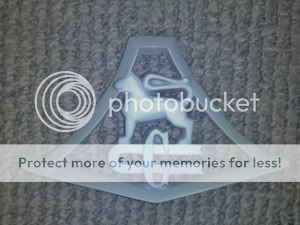

After some sealing and shaping with the poly filler and automotive paint putty, I took a silicone mould of the emblem and created a resin version. This was further worked and corrected and then another silicone mould was taken. Resin versions containing aluminium powder then were created.

Mounting screws were bonded in and this version of the emblem has now been sent off for chrome plating. I also intend to send another emblem off to get a price on having it cast in metal, but I suspect that this may be excessive.

Edited by user

12 years ago

|

Reason: Not specified

Mark - Owner of 2 under restoration Australian coachbuilt Ascorts.